山东轩烨机器人科技有限公司是一家以工业机器人以及自动化非标设备于一体的技术企业,公司致力于焊接、切割、机器人机床上下料等领域的机器人智能化研究和产业化应用

公司立足于高端装备制造等战略新兴产业,将追逐“制造2025"致力于机器人技术和互联网技术的深度融合,推动智造。

发布:2024-03-27 浏览:0

1、提高了生产效率。手工焊在对不锈钢制品的焊接中会随着工人的工作时间造成焊接效率低下,不锈钢焊接机器人可以实现焊接过程自动化连续工作,重复动作不会受到时间和环境等因素的影响,提高了焊接效率。

1. Improved production efficiency. Manual welding in the welding of stainless steel products can lead to low welding efficiency with the working time of workers. Stainless steel welding robots can achieve automatic and continuous welding process, and repetitive actions are not affected by factors such as time and environment, improving welding efficiency.

2、减少了企业的成本支出。焊接市场中的不锈钢焊接机器人的价格在几万到十几万不等,相当于一名普通焊接工人的年工资,不锈钢焊接机器人的使用寿命长达数十年,给用户带来的生产效益较高。

2. Reduced the cost expenditure of the enterprise. The price of stainless steel welding robots in the welding market ranges from tens of thousands to hundreds of thousands, which is equivalent to the annual salary of an ordinary welding worker. The service life of stainless steel welding robots can reach several decades, bringing high production efficiency to users.

3、解放了工人的劳动强度。传统焊接中,工人会直接接触有害气体、激光、焊接烟尘、磁场等,对人体造成危害,不锈钢焊接机器人可实现焊接过程自动化,人工远离焊接范围,减少了职业病的发生率。

3. Liberated the labor intensity of workers. In traditional welding, workers are directly exposed to harmful gases, lasers, welding fumes, magnetic fields, etc., which pose a threat to human health. Stainless steel welding robots can automate the welding process, keeping manual labor away from the welding range and reducing the incidence of occupational diseases.

4、重复定位精度稳定。不锈钢焊接机器人根据型号不同,重复定位精度都维持在0.1mm以下,焊点在重复动作中也不会发生偏移,焊接精度高,对焊缝焊接精准。

4. Stable repetitive positioning accuracy. The stainless steel welding robot maintains a repeated positioning accuracy of less than 0.1mm according to different models, and the welding points do not deviate during repeated actions, resulting in high welding accuracy and precise welding of the weld seam.

5、提供了较多的工作岗位。不锈钢焊接机器人的生产、安装、调试、操作、维护保养都需要工人进行,未来的焊接市场自动化和智能化水平会不断发展,实现自动化就业不仅会提升自身技能,还会使薪资水平提高一大步。

5. Provides a wide range of job positions. The production, installation, debugging, operation, and maintenance of stainless steel welding robots all require workers to carry out. The automation and intelligence level of the welding market will continue to develop in the future. Achieving automation employment will not only improve one's own skills, but also significantly increase salary levels.

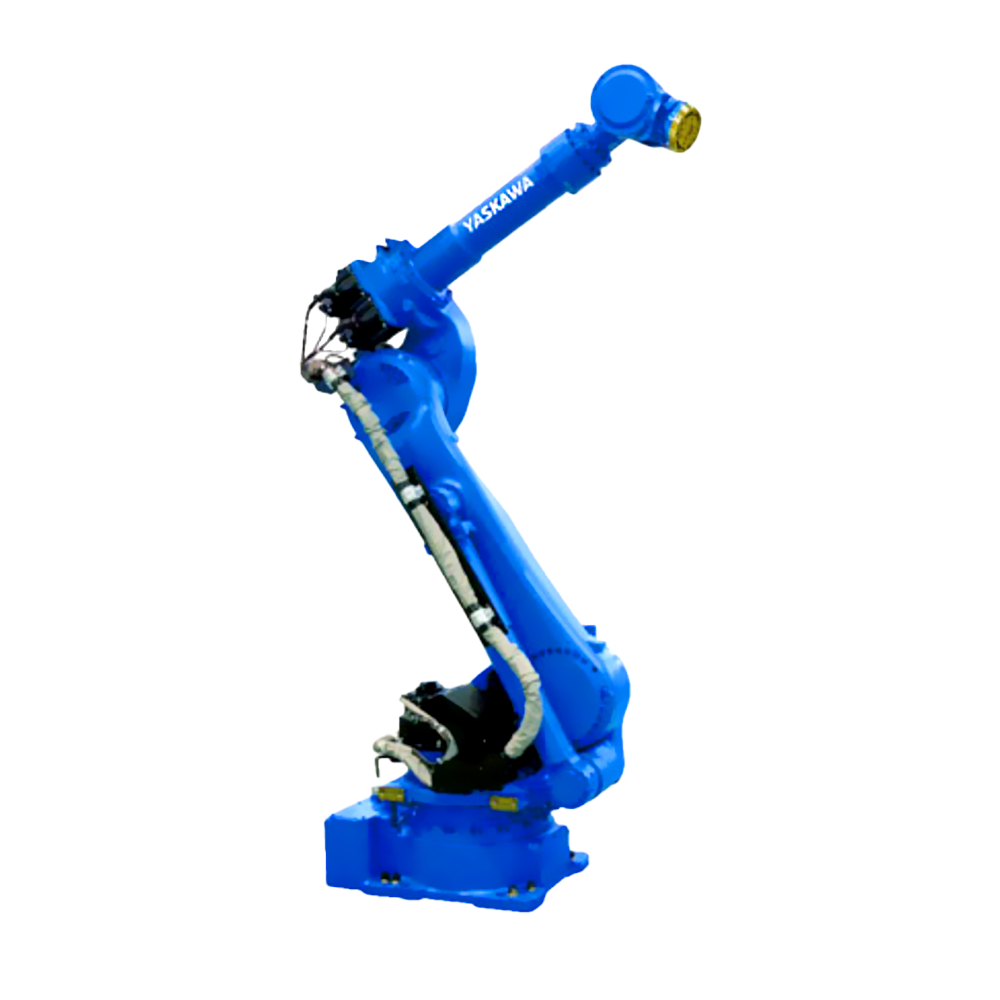

本文由安川机器人提供技术支持,更多的详细精彩内容请点击我们的网站https://www.xuanyerobot.com,我们将会全心全意为您提供满意的服务。

This article is supported by Yaskawa Robotics. For more detailed and exciting content, please click on our website https://www.xuanyerobot.com We will wholeheartedly provide you with satisfactory service.

截屏,微信识别二维码